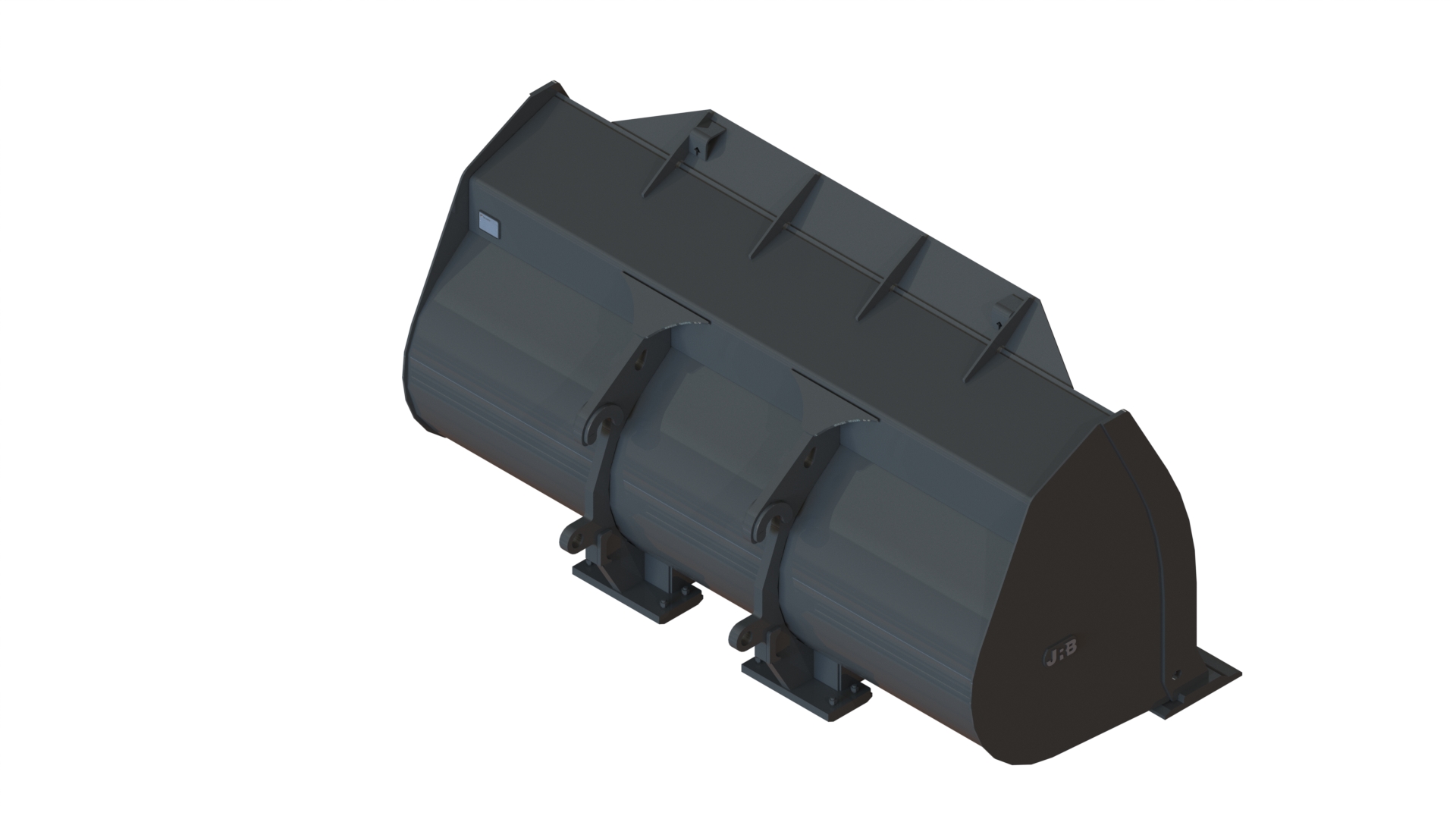

SharkBite™ Grapple for Class II Forks

SharkBite™ installs onto any ISO-standard class II ITA fork rail, transforming a regular set of pallet forks into an ultra-versatile grapple. Optional bolt-on Shark Teeth extend the durability and gripping performance of SharkBite, and the high-strength steel construction and powder-coat finish means SharkBite is built to last.

- FEATURES

- SPECIFICATIONS

- INDUSTRIES

- LITERATURE

- FAQs

- Broad range of motion — 117 degrees in total

- Can be attached to any standard Class II ITA fork frame

- Great clamping ability for a variety of applications

- Installs/uninstalls in just 5 minutes — no tools required

- High-strength steel construction for enhanced durability

- Optional Shark Teeth made from AR400 hardened steel

Specifications

| Specifications | Standard Measurements (in) | Standard Measurements (m) |

|---|---|---|

| Weight | 175 lbs | 79.3 kg |

| Minimum Load Diameter | 14 | 0.36 |

| Overall Height | 63.5 | 1.61 |

| Depth | 46.3 | 1.18 |

| Min. Envelope | 7.3 | 0.19 |

| Pass-Thru | 7.3 | 0.19 |

| Range of Motion | 117° | 117° |

| Width | 13 | 0.33 |

PALADIN SharkBite™ FAQ

What applications are ideal for SharkBite?

SharkBite is ideal for handling large piles of brush and logs and for securing concrete slabs and boulders, even when the forks are tilted forward. Forks should never be used for prying, regardless of load rating.

How does SharkBite ship?

SharkBite ships ready-to-use: fully assembled, banded to a wooden pallet, greased, and with hoses and QDs installed.

What is the recommended fork tine length?

SharkBite is about 46” long when positioned straight out, so users will get the best results when using 48” forks, however other lengths of forks will also work, depending on application.

Does SharkBite require minimum capacity forks? Should users reduce their fork rating by a certain weight to compensate for SharkBite?

Users should consider their application when selecting the appropriate forks to use with SharkBite and add 2,000 LBS of effective additional load to compensate for SharkBite’s grip.

What is SharkBite’s clamping force?

“Clamping Force” is not an industry-standard performance measurement, and users should be cautious of claims referring to clamping force, especially when the stated clamping force exceeds safe load ratings of the forks.

How does SharkBite affect tipping load?

On most machines, the effect on tipping load will be unnoticeable to operators. SharkBite weighs about 175 LBS, and its CG is only a few inches forward from the hitch.

Can I use SharkBite on a mini skid steer, mini track loader, or compact tool carrier or equipped with a Class II fork frame?

SharkBite is designed for use on skid steers and compact track loaders. Most mini skid loaders and similar-sized equipment will not have sufficient fork tine rating or lift capacity to fully utilize SharkBite.

Does equipment with high relief pressures require a pressure relief / case drain?

SharkBite is rated to 3500 PSI.

How does SharkBite affect warranty on other manufacturer’s fork frames?

SharkBite is designed to be installed on any fork frame that adheres to the Class II ITA standard, but Paladin can only provide warranty on Paladin products within their defined warranty periods. Users should consult the respective operator’s manuals of their fork frames for any warranty coverage and permitted uses.

NOTE: Users should always read the operator’s manual when operating attachments or equipment. There are additional safety considerations contained in the operator’s manual.