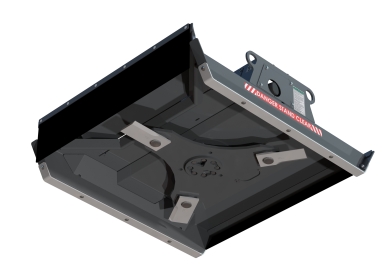

Mini-Excavator Brush Cutter

Paladin is expanding its offerings for mini-excavators with a new line of brush cutters, the MX Series. The MX Series is compatible with 3mT - 10mT mini-excavators, and facilitates a variety of applications, including over-fence brush management, embankment and ditch management, and rail right-of-way management.

With a solid formed T-1 steel deck and reversible AR400 cutting blades, the MX series can efficiently process brush and trees up to 6” in diameter. Equipped with Paladin’s bolt-on mounting system, it offers a seamless configuration to a variety of coupling systems; if coupling requirements change, units can be quickly and easily reconfigured without welding or grinding, even in the field.

- FEATURES

- SPECIFICATIONS

- INDUSTRIES

- LITERATURE

- FAQs

Prime Mover: Mini-Excavator

- Heavy-duty hinged debris shield retracts when the head is engaged with trees and brush, exposing the blades and allowing for aggressive cuts at maximum blade engagement

- Fore and aft curtain shielding dampens debris projection and gives operators more control, making it easier to operate in areas where debris projection is a concern

- Automatic hydraulic braking stops blade rotation 10-15 seconds after the machine is turned off, making it faster for operators to get out of the cab

- Direct-drive hydraulic motor with heavy-duty bearing housing, ensuring long hydraulic life

- All models operate without a case drain, for maximum versatility across machines

- Large cutting size, up to 6", for clearing large areas and trees more efficiently

- Powder coat finish, for maximum rust and erosion protection

| Model | Mini Excavator | Flow (gpm) | Cutting Width (in) | Max. Brush Size (in) | Dimensions (ex. pallet) (in) | Weight (lb) | Adapter Pattern |

|---|---|---|---|---|---|---|---|

| BC40MX10 | 3mT-6mT | 13-19 | 40 | 4 | 47 x 52 x 22 | 660 | A |

| BC40MX20 | 3mT-6mT | 19-26 | 40 | 4 | 47 x 52 x 22 | 660 | A |

| BC50MX10 | 5mT-8mT | 17-22 | 50 | 5 | 57 x 63 x 24 | 1,050 | B or C |

| BC50MX20 | 5mT-8mT | 22-34 | 50 | 5 | 57 x 63 x 24 | 1,050 | B or C |

| BC60MX10 | 7mT-10mT | 20-28 | 60 | 6 | 67 x 73 x 26 | 1,240 | B or C |

| BC60MX20 | 7mT-10mT | 28-35 | 60 | 6 | 67 x 73 x 26 | 1,240 | B or C |

What are the MX Brush Cutter’s safety features?

We believe safety and productivity go hand-in-hand. When operators are safe, they work with more confidence and see increased outputs. The MX has several unique safety features that help operators get more done and stay safe at the same time:

- Hinged debris shield: On the operator's left-hand side of the head, there is a hinged debris shield that lifts when users engage brush and trees, exposing the blades and providing an extremely aggressive cut at full-depth. The shield provides the best of both worlds: covered blades when the cutter is not in use and exposed blades when the cutter is engaged.

- NEW TiltLatchTM: The TiltLatchTM is a patent-pending hook design that prevents the debris shield from opening due to gravity when the cutter is curled beyond a certain angle, ensuring debris is blocked, and allowing for optimal cuts.

- Automatic hydraulic braking: This feature ensures blade rotation is shut off 10-15 seconds after the flow is stopped, allowing operators can get in and out of the cab safely and efficiently, without worrying about lingering blade rotation.

Does the MX Brush Cutter have a mulching feature?

No, this product will not substitute for a mulcher. The three blades are directionally beveled so debris is pushed into the head of the cutter, creating finer debris (for easier recycling) than other cutters. However, if you need mulching capabilities, please consider our other mulching products.

How many blades does the MX Brush Cutter have? How often they need to be replaced?

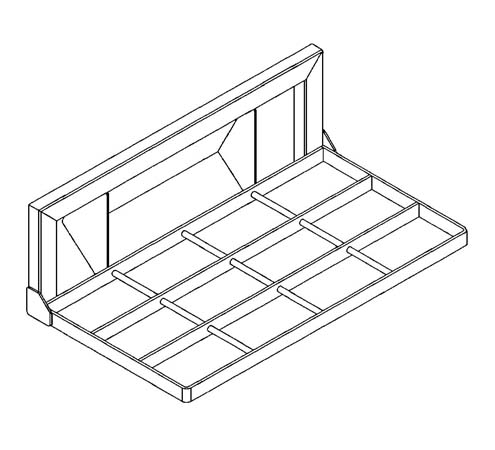

The MX Brush Cutter uses three swinging blades mounted to a triangular blade carrier to maximize performance. The cutter rotates in one direction, and the blades themselves are reversible, so when the leading-edge wears, operators can unbolt the blade, flip it over, and use the other side. Many application factors would influence a blade’s life, but blades and their replacements are made from a special hardened, abrasion-resistant steel designed specifically for this application. All MX models use identical blades, so the same blades will work for all.

What’s the difference between the MX Brush Cutter and the Flail Mower?

The MX Brush Cutter can handle heavier brush, is more versatile (doesn’t require a case drain line), is compatible with our top-cap system, and has greater debris control. The Flail Mower, however, might be the right product for you for applications like finish mowing, if you have unique storage/transportation requirements, or if you’re seeking a product that is thumb-compatible.

What’s the difference between the MX Brush Cutter and the GroundSharkTM Brush Cutter?

The MX Brush Cutter is designed to bring more versatility to your mini-excavator and allow you to accomplish some unique applications. With this product and the reach provided by mini-excavators, difficult areas like embankments, over fences, and high-reach areas are more accessible. If you are looking are an attachment for your skid-steer, or need mulching capabilities, however, the GroundShark might be best for your project.